Flange Guard Safety Shields

Safety or spray shields offer the last line of defence. They are not designed to contain the leak indefinitely, but to prevent the harmful spray outs resulting in fire or explosions causing considerable plant down time, capital expenditure and even loss of life.

Installing our safety shields is both simple and quick, requiring no tools.

Flexitallic Australia can assist you identify Safety Shield solutions for applications such as:

- Acid and Alkali

- Steam

- Oil Mist

- Thermal Oil

- Liquified Natural Gas (LNG)

- Mono-ethylene glycol (MEG)

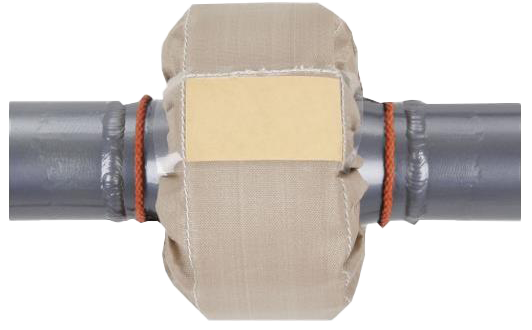

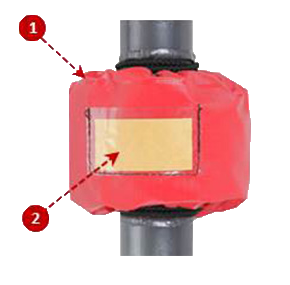

Sureband Steel

SUREBAND STEEL shields use only the highest quality materials. This simple design outlasts all other shield types/materials due to rigorous pressure testing. All 316 ST/ST banding and mesh. Suitable for high pressure and temperature applications. Most important is the internal multi-layered steel mesh, which effectively diffuses pressure releases – thus preventing spray and mist formation. Sureband Steel safety shields are recommended for LNG applications.