Global Gasket Manufacturer

and Sealing Solutions

In Australia

Global Gasket Manufacturer and Sealing Solutions in Australia

About Us

Flexitallic Australia manufactures and trades a variety of high quality products designed for fluid sealing applications in the industrial and manufacturing sectors.

Our company ethos is to provide honesty, reliability and a high level of service and dependability through all aspects of our business, adding value to our products and ensuring we sustain a competitive edge.

Flexitallic Australia continues to invest in Quality Systems recognised all over the world, such as ISO 45001:2018, ISO 14001:2015 and ISO 9001:2015. Our products are traditional in function but our outlook is progressive and evolving.

Flexitallic Australia is a major supplier and manufacturer of flow and sealing products for demanding applications throughout various industries.

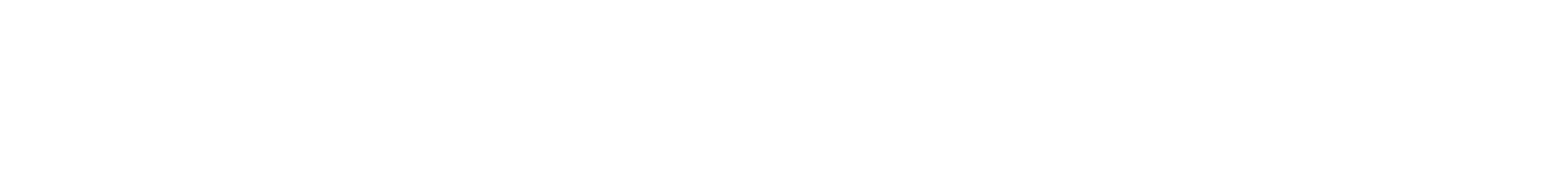

Products – Overview

Flexitallic remains at the forefront of developing sealing solutions for industries across the world. Flexitallic offers a wide range of high quality standard gaskets and customised sealing solutions that allow customers to operate their plants, complete projects and start up from shutdowns safely and efficiently. These products include:

- Rubber

- Unipac Compression Packings

- Flange Guard Safety Shields

- Finger Savers

- Staub Pipe Couplings

- PTFE Jointing and Sealing – Sigma®/Uniflon™

- Sheet Jointing/CNAF

- Thermiculite® 815 – High Temperature Gasket Material

- Semi-Metallic Gaskets, Spiral Wound Gaskets

- Corriculite® filler material for corrosion protection

- Ring Type Joints

- Joint Integrity Services

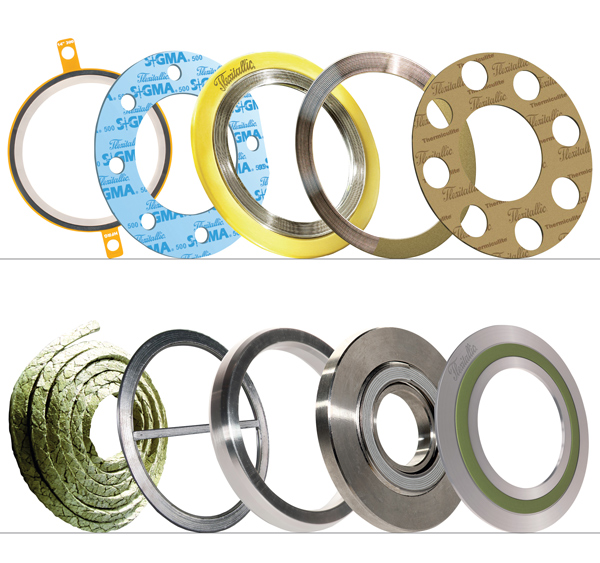

PTFE Jointing and Sealing – Sigma®/Uniflon™

Utilising a unique manufacturing process exclusive to Flexitallic, SIGMA® represents the latest generation of multidirectional PTFE materials, which offer very high chemical resistance in processes ranging from cryogenic temperatures to 260°C.

All SIGMA® materials and PTFE filled seals/gaskets are FDA compliant, making them ideal for use in industries where product contamination is of concern.

- Sigma 500, 511, 533 ePTFE, 850 ePTFE

- FDA compliant seals/gaskets

- Gasket/Seals for chemical, pharmaceutical, food

- Gasket/Seals for cryogenic applications

- Reactor Seals/Gaskets

- Teflon Seals/Gaskets

Unipac Compression Packings

In addition to our sheet and gasket products, Flexitallic Australia offer a full range of compression packings for valve, rotary pump, and reciprocating pump applications.

Our packings utilise the most advanced production technique and materials to ensure high integrity even in the most demanding of industrial applications.

Material constructions include PTFE, Graphite and carbon fibre and synthetic fibres in a variety of combinations. For high performance valve applications, we manufacture exfoliated graphite die formed rings in virtually any size, section or density to suit requirements.

Straub Pipe Couplings

Available exclusively through Flexitallic Australia, the STRAUB Pipe Repairing System offers an extensive range of pipe damage control above and below ground including systems under pressure.

STRAUB’s light-weight wrap-around pipe repair clamps are available in narrow (32.0mm) and wide (700.0mm) casing widths to contain pin-holes, cracks, corrosion blisters, and large hole damage.

Flange Guard Safety Shields

Pipe safety shields also known as flange guards are used in a variety of industries, where their primary application is the prevention of harmful spray-outs and mist formation from failing pipe joints, of toxic, corrosive and dangerous liquids such as acid, oil or steam.

Safety or spray shields offer the last line of defence. They are not designed to contain the leak indefinitely, but to prevent the harmful spray outs resulting in fire or explosions causing considerable plant down time, capital expenditure and even loss of life.

Finger Savers

Flexitallic Australia are authorised distributors for the FingerSaver throughout Australia.

Every day in many industries, people are sustaining hand and finger injuries that are preventable. Using the correct safety device should be an essential part of everyday life. If you are working in areas where objects could hit you on the head, you would wear a hard hat. If your eyes are at risk from foreign objects or wind blown particles, you would wear safety glasses.

Think about your hands in the same way! Be sure to keep them safe and out of harms way, be sure to use the Fingersaver; don’t take risks with your hands.

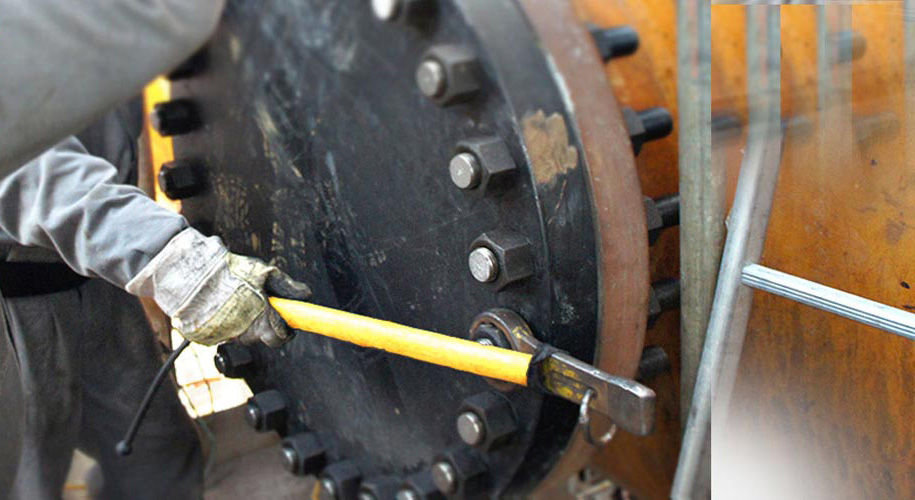

Joint Integrity Services

Our team of application engineers understand that the use of high quality seals/gaskets are not a guarantee of sealing success. As a result, Flexitallic application engineering offer a range of Joint Integrity and Technical Services that are designed to complement and enhance Flexitallic’s product offering.

Allowing customers to operate their plants, complete projects and start up from turnarounds safely and efficiently. Our goal is to help customers achieve leak free start-up and operation within the scheduled maintenance cycle.

- Shutdown support

- 13555 Sealing material characteristic values

- EN 1591 calculation for gaskets

- Gasket installation training – 1591-4

- Gaskets to VDI 2290, VDI 2240, TA Luft

- Gasket assembly support

- Application consulting and design

- Research and Development Lab (R&D)

- AMTEC Test benches

- AMTEC High Temperature testing